About

Introduction

"Since 1977, Brasdaq has been a leader in communication and control system design, manufacturing, and implementation. Our journey of innovation and excellence has been marked by establishing strategic partnerships worldwide, reflecting our commitment to global collaboration and expertise.

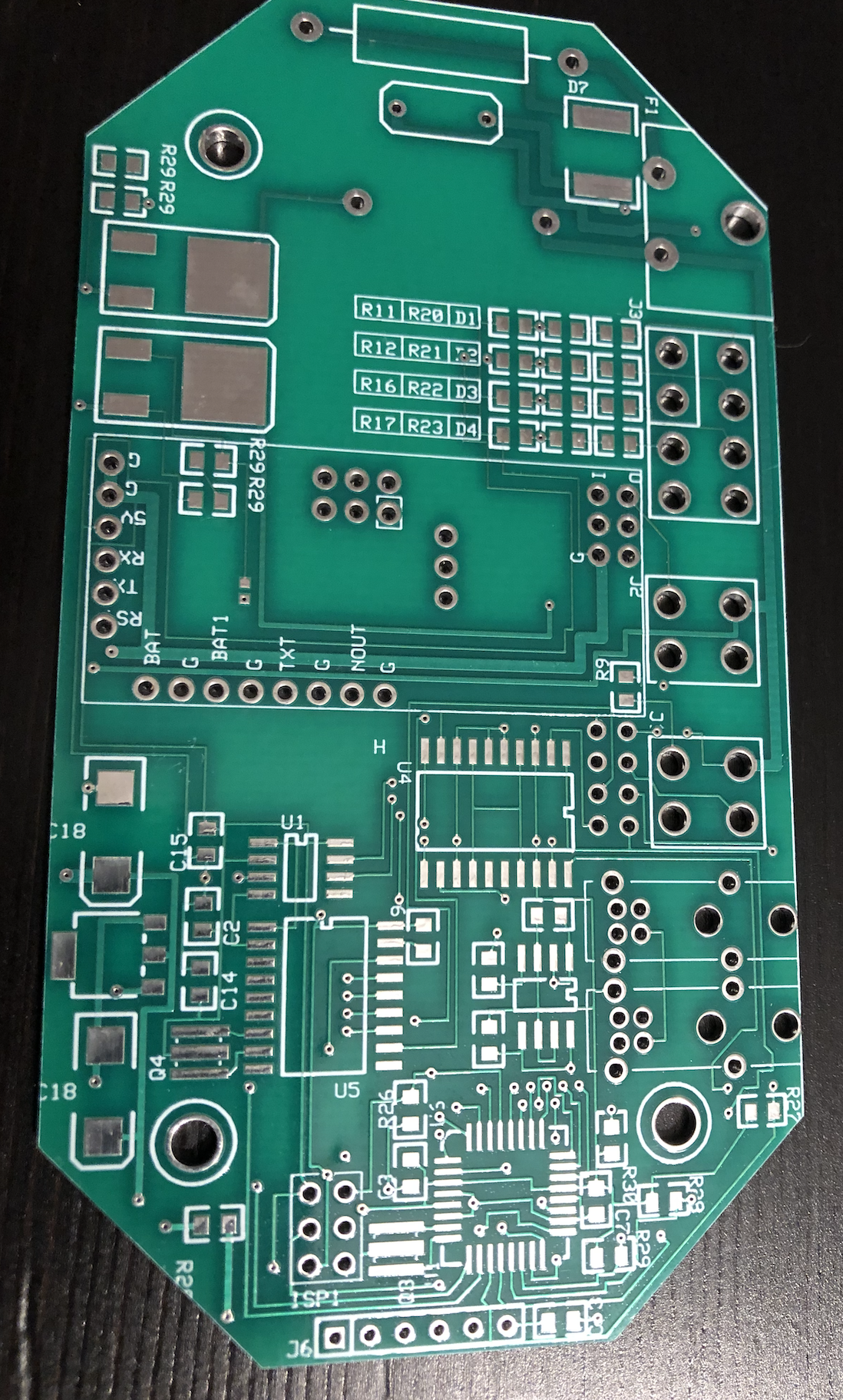

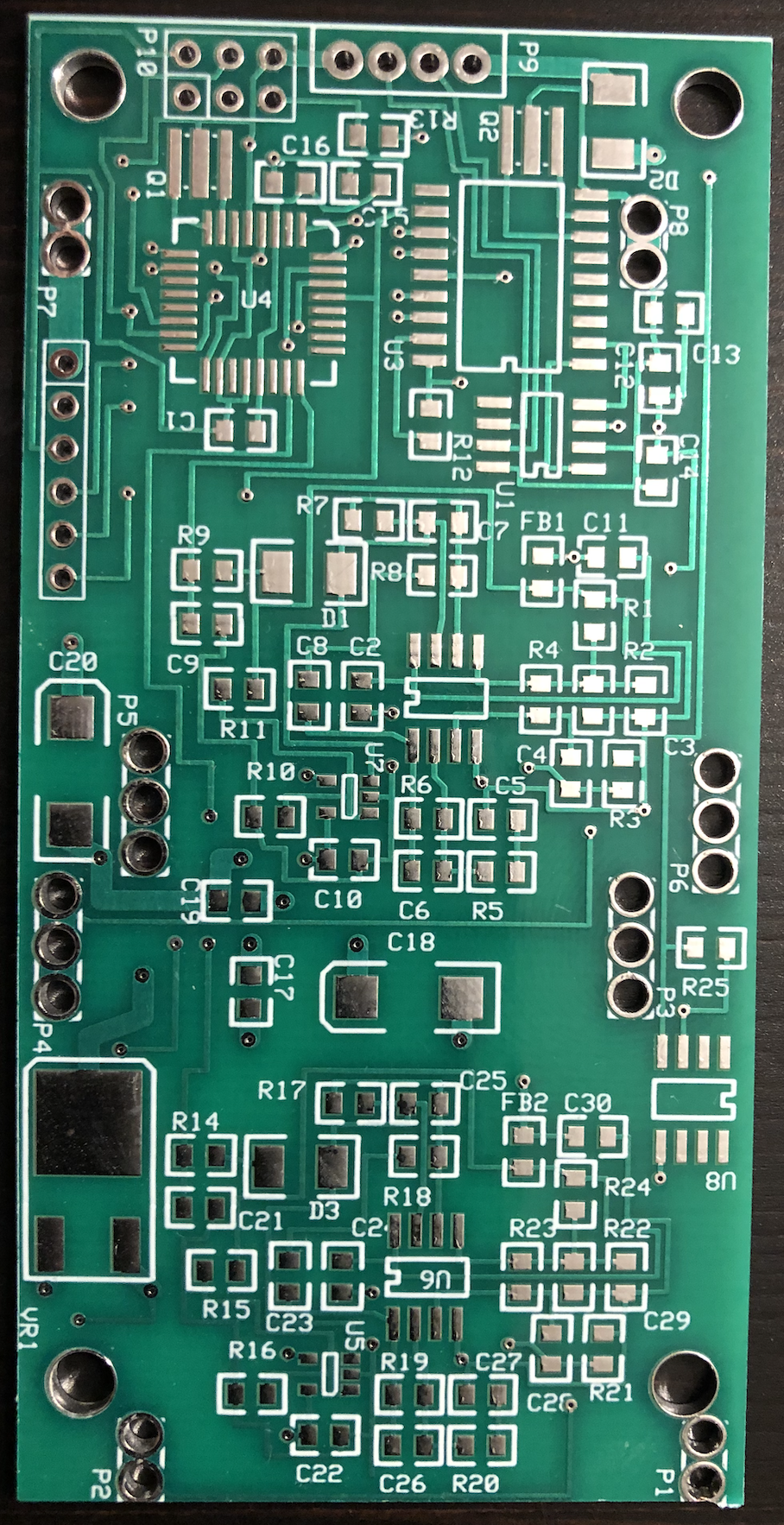

In 2016, we expanded our horizon by launching a team in Indore, India, specializing in leading-edge PCB hardware design and app development. This move further strengthened our position as a pioneer in technology solutions. Additionally, with two representatives in Shenzen and Shanghai and an office in Nanchang, China, we've enhanced our capabilities in supplier quality inspections, sourcing, and engineering.

Our team's expertise is supported by two dedicated reverse engineers in our USA main office, equipped with the latest hardware and software tools. This ensures we provide consistent, rapid, and high-quality results to our clients. At Brasdaq, continual investment in our contributors is a priority. We focus on training and expanding our portfolio, which includes PCB schematic extraction, code extraction, network reverse engineering, 3D scanning, mechanical modeling, and various 3D printing technologies.

Our approach to innovation involves close collaboration with local suppliers, enabling us to deliver quick proof of concept solutions and iterate designs efficiently. This collaborative model allows us to debug and finalize designs rapidly, ensuring that our clients receive the most effective solutions in the shortest possible time.

Furthermore, we manage the life cycle of designs and components meticulously, guaranteeing uninterrupted supply chains for our customers. Our global reach, combined with a deep understanding of local markets, positions Brasdaq as a versatile and reliable partner in technology solutions, from concept to completion.

Beyond developing cutting-edge products, Brasdaq excels in creating bespoke tools essential for specialized projects. Our unique strength lies in our ability to innovate tools that are not available off-the-shelf but are crucial for the success of a project. This capability to custom-develop tools as per project requirements sets us apart and is a cornerstone of our approach. It allows us to deliver solutions with unmatched speed and accuracy, tailored precisely to the needs of each project. This adaptability and ingenuity in tool development ensure that we not only meet but often exceed the expectations of our clients, reaffirming our commitment to delivering excellence in every endeavor.

At Brasdaq, we don't just create solutions; we engineer a future that's more connected, efficient, and innovative."

Company

About brasdaq

In 2014, Brasdaq acquired capabilities for testing products that achieve ISO and SAE standards in partnership with accredited laboratories and institutions. We use the latest test methodologies and equipment to provide the most accurate results. In 2015, we developed the first products that combined GPS, GSM and 2.4Ghz technology with our extensive transportation communication network portfolio.

In 2017,we partnered with a experienced PCB manufacturer (Pergamon Corporation) for manufacturing of components as well as help control our supply chain and manufacturing for products related to safety and supervision. Working closely with out customer Transportation Accessories Group, our team implemented the first of its kind wholly integrated vision survalence system communicating between modules using our proprietary CAN driver stack between control module, vision module and doppler module. We also developed the world’s first off-road ATV comprehensive data acquisition and display product.

Company

History

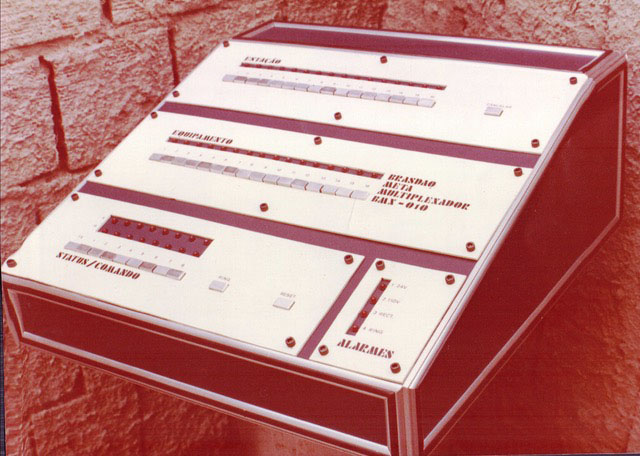

Brasdaq Facility in 1977 in Rio de Janeiro, Brazil

Multiplexer for communication and control

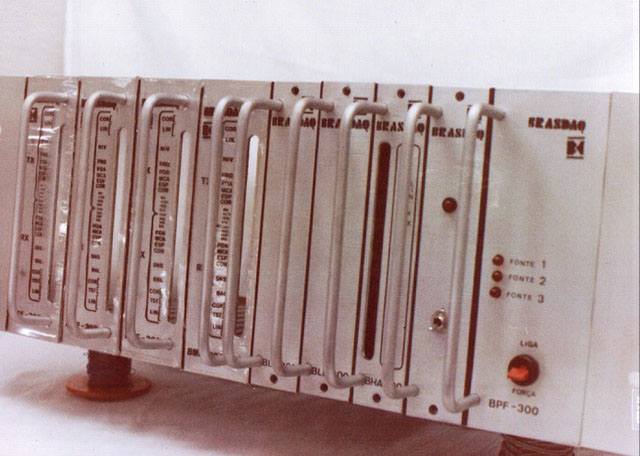

RF transmitted/reviver for voice and control

Products

Our Current Products

Terms of service are rules by which one must agree to abide in order to use a service.

Terms of service can also be merely a disclaimer, especially regarding the use of websites.

Our Capabilities

Services

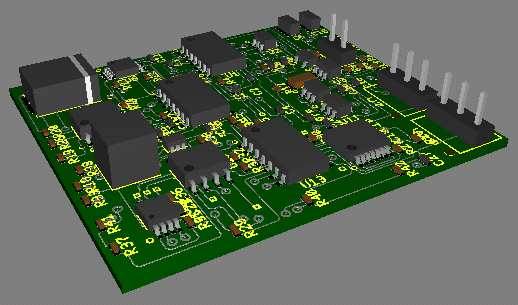

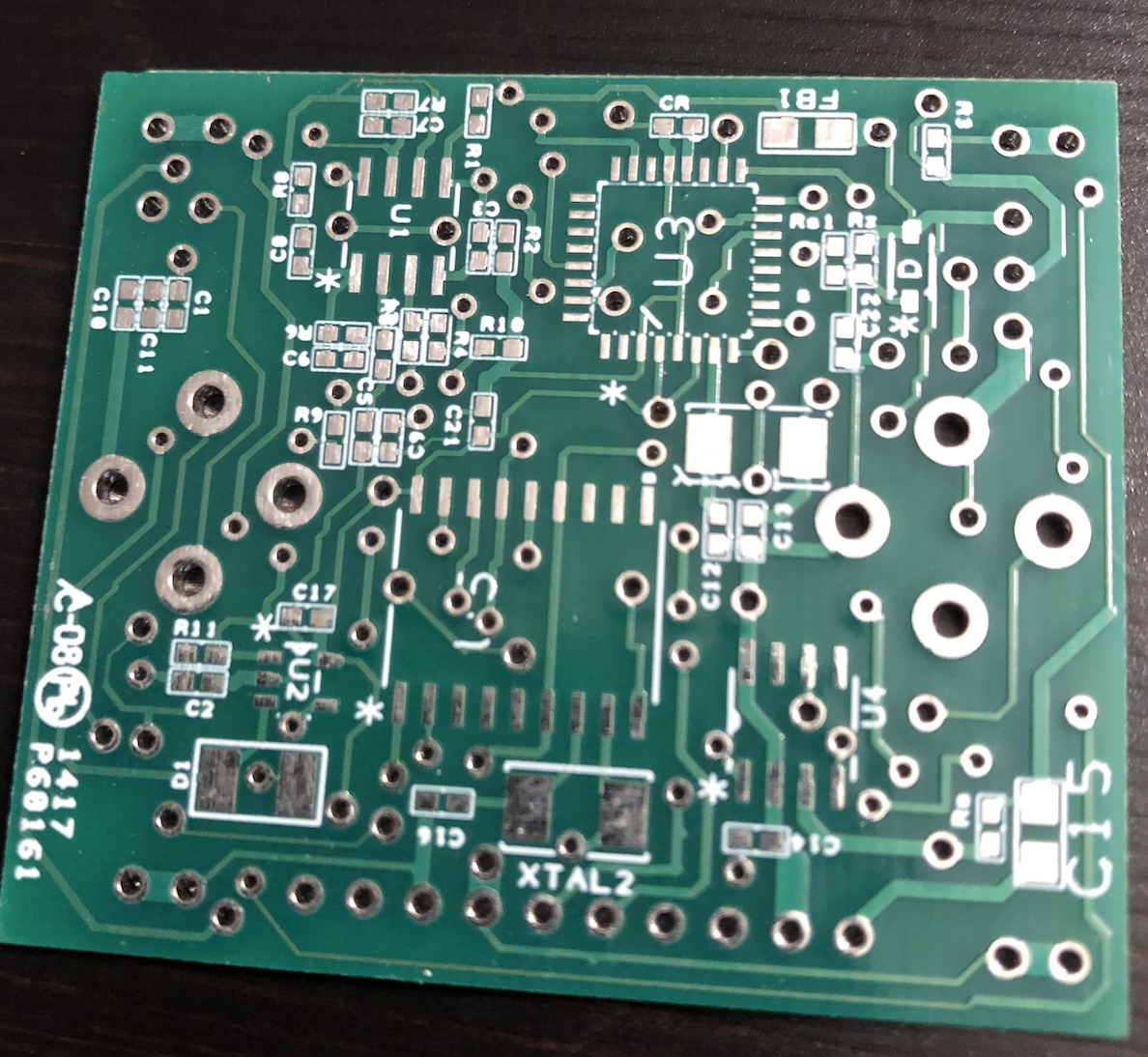

Pcb reverse engineering

Brasdaq stands at the forefront of technological innovation with its advanced capabilities in PCB reverse engineering, setting a new industry standard in circuit analysis and replication. Utilizing state-of-the-art circuit extraction software, our team expertly navigates the complexities of any PCB, unraveling its intricacies with unparalleled precision. This sophisticated software not only aids in meticulously tracing connections but also ensures the accuracy and efficiency of our schematic extractions. Our expertise extends to comprehensive component identification, where we meticulously catalog each element, decoding everything from the most rudimentary resistors to the most complex integrated circuits.

Beyond mere identification, our prowess in functional analysis allows us to delve deeper, examining the operational aspects of each component under real-world conditions. This thorough approach ensures that we don’t just replicate PCB designs; we understand and enhance them, embodying the cutting edge of reverse engineering. At Brasdaq, we don’t just keep pace with technology; we redefine its boundaries, providing solutions that are as innovative as they are reliable.

Code extraction

At Brasdaq, our prowess in code extraction for integrating new designs into existing module networks epitomizes the zenith of technological sophistication. Our methodology is underpinned by the deployment of advanced tools and cutting-edge software, enabling us to meticulously simulate an exhaustive array of scenarios and conditions. This rigorous approach is not just about ensuring compatibility; it's an intricate dance of engineering finesse and precision analytics. We delve deep into the labyrinth of code, extracting and dissecting each strand to harmonize our novel designs with the established systems seamlessly.

Our process is a complex symphony of algorithms and simulations, where every possible interaction is anticipated, analyzed, and accounted for. This ensures that our final designs are not just additions but are fully integrated components that enhance the overall system without conflicting with any existing functions. At Brasdaq, we don't just engineer solutions; we craft intricate technological ecosystems that are robust, fully supported, and flawlessly integrate.

Mobile app development / implementation and hosting

At Brasdaq, our app development process is anchored in the utilization of the most current and sophisticated development tools, ensuring that our applications are not just cutting-edge, but also robust and scalable. Our team's extensive experience in implementing APIs allows us to seamlessly integrate diverse functionalities, enhancing the app's capabilities and user experience. We understand the critical nature of APIs in creating interconnected systems that communicate flawlessly, both internally and with external services. Moreover, our commitment to excellence is further exemplified in our rigorous approach to creating test environments.

These environments are meticulously crafted to simulate real-world scenarios, enabling us to identify and address potential issues early in the development cycle. This proactive approach to testing ensures that our applications are not only functionally sound but also deliver a seamless user experience. At Brasdaq, professionalism and precision in app development are not just goals; they are standards we uphold in every project we undertake.

Development and preparation Of design specification and production documentation

At Brasdaq, our expertise in developing detailed design specifications is not just a service; it's a partnership with our customers to ensure efficiency and precision throughout the product lifecycle. We engage closely with our clients to create specifications that minimize the need for re-designs and delays, streamlining the path to rapid First Article Inspection (FAI) samples and initial production runs. This collaborative approach is ingrained in our ethos, ensuring that every project benefits from our extensive experience and deep understanding of the nuances in product development. Once a product is deemed production-ready by our customers, we seamlessly transition to creating concise and accurate production documentation, fully compliant with all relevant industry ISO standards.

Our commitment extends beyond documentation; we offer in-person production support and conduct thorough audits at the customers' chosen sub-contract manufacturing facilities. This hands-on involvement is a testament to our dedication to not only meeting but exceeding expectations in every phase of the product lifecycle, making this process almost second nature to us at Brasdaq.

Testing and validation

At Brasdaq, our testing capabilities are a cornerstone of our commitment to delivering products of the highest quality and reliability. We offer a comprehensive suite of testing services, crucial for design validation and ensuring that our products meet and exceed industry standards.

Thermal Testing: Our in-house thermal testing procedures are meticulously designed to simulate a range of temperature conditions. By subjecting our electronic modules to extreme heat and cold, we validate their endurance and performance, ensuring they operate flawlessly under any thermal stress.

EMI Testing: Electromagnetic Interference (EMI) testing is vital to certify that our products meet regulatory requirements and function seamlessly in electronic environments. Our EMI testing capabilities ensure that our designs are not just effective but also resilient in the face of potential electromagnetic disruptions.

Environmental Testing: Understanding the critical nature of environmental resilience, we conduct thorough environmental testing. This includes water intrusion tests, to ensure watertight integrity; salt spray tests, to verify corrosion resistance; and vibration testing, to confirm structural robustness. These tests simulate real-world environmental conditions, providing confidence in the durability of our products.

Extended Network for Specialized Testing: Recognizing the diverse needs of our products and clients, we extend our testing capabilities through a network of certified testing labs. This network allows us to conduct specialized tests, including FCC compliance and other industry-specific standards, providing a comprehensive testing regimen that covers every possible requirement. At Brasdaq, our testing isn't just a phase in the development process; it's an integral part of our engineering culture. We pride ourselves on a testing regime that is as thorough as it is efficient, ensuring that every product not only meets but exceeds the expectations set forth by our clients and regulatory bodies. This dedication to excellence in testing is a testament to our unwavering commitment to quality and reliability in every project we undertake.

JOIN US

Contact

Have questions? We’re happy to help.

- +1 267 281 4011

- info@brasdaq.com